SUPERSCAN-T INDUSTRIAL

ACTIVE INFRARED PRESENCE SENSOR

Description

ACTIVE INFRARED PRESENCE SENSOR

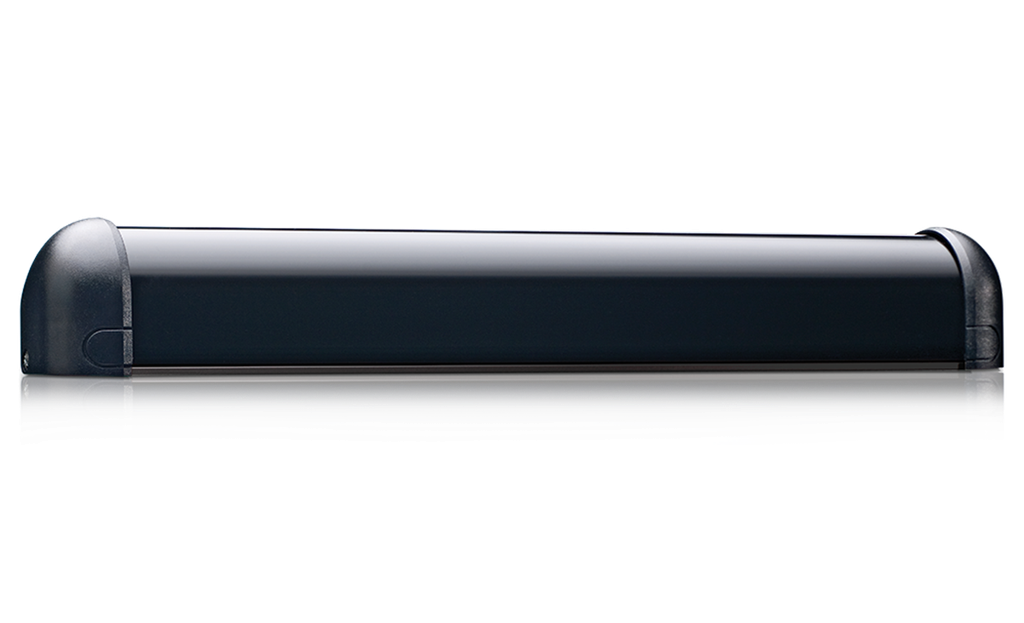

BEA’s SUPERSCAN-T INDUSTRIAL is an active infrared sensor designed for use in industrial environments that require presence and/or safety detection. This sensor can be used on automatic industrial doors, gates and industrial automation applications.

The SUPERSCAN-T INDUSTRIAL uses triangulation to detect the presence of an object, eliminating false detections caused by varying ground and environmental conditions.

In an industrial setting, this versatile sensor can be mounted stationary or on a moving object. Additionally, the SUPERSCAN-T INDUSTRIAL can be used as an individual module or daisy chained with up to 8 secondary modules (9

total modules). This flexibility allows the SUPERSCAN-T INDUSTRIAL to be used on both narrow and wide doors and many other off door applications. Each module detection zone can be angled independently.

Features

-

Fit to the application

Housing available up to 96 inches; can be field-cut to desired door width

-

User-defined detection zones

Detection zone of 24 to 96 inches

-

Adjustable detection zone

Can be set to background analysis mode to reduce the change of false detection from faulty environmental situations

-

Standards compliant

Capable of external monitoring

Barrier Arm Safety Without Pavement Sawing by Metro Fence

Read more

See all our segments

-

-

Doors & Windows

-

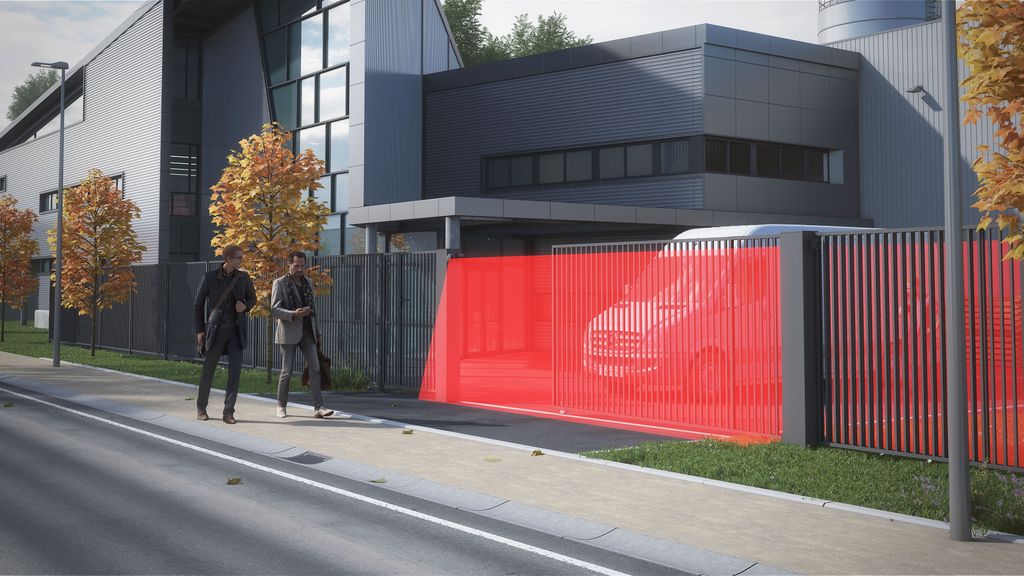

Security & Access Control

-

-

-

Doors

-

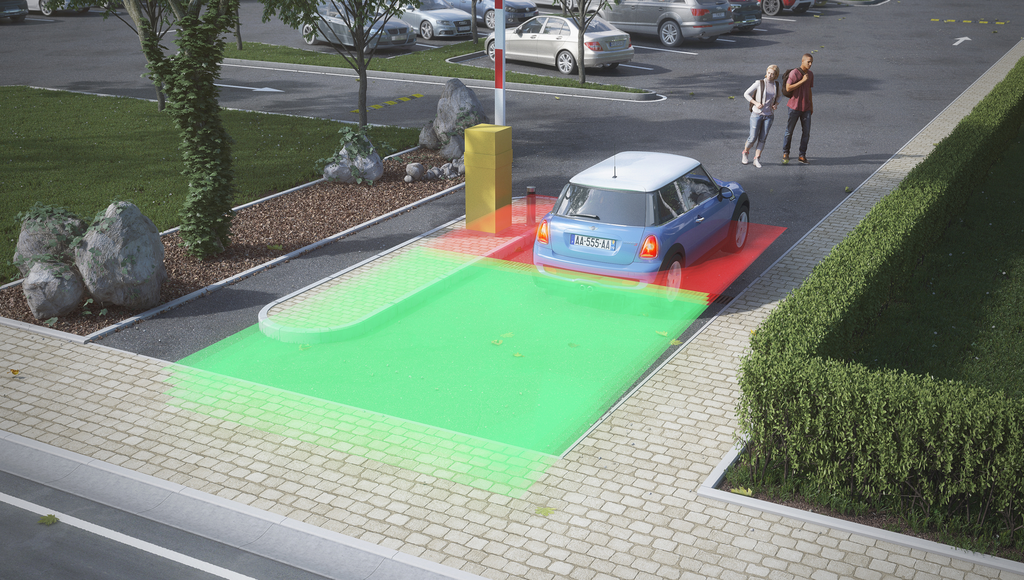

Gates & Barriers

-

-

-

Autonomous Robots

-

Traffic & Transport Solutions

-

Asset Protection

-